WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Calculate Top Ball Size of Grinding Media -FRED C. BOND Equation & Method Although it was developed nearly 50 years ago, Bond 's method is still useful for calculating necessary mill sizes and power consumption for ball and rod mills.

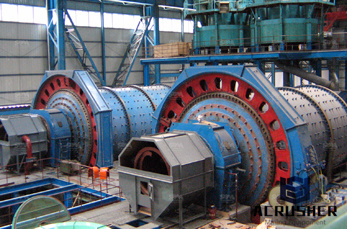

Figure 8.2 Media motion in the tumbling mill. 8.1 Grinding 8.1.1 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types - rod, ball, pebble autogenous and semi-autogenous. The grinding action is induced by relative motion between the

Calculation of grinding media in raw mill Art, calculation of grinding media in raw mill, calculate the grinding media in cement mill. effects of grinding media shapes on ball calculate the grinding media in cement mill mill, Grinding media sorting is performed when the ball load wears .

by Erdem (2002) for dry multi-component cement grinding ball mills, using the results of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill power draw for a given mill is required for the calculation of power draw. Morrell (1996) proposed a

cement mill grinding media calculation - . cement mill grinding media calculations – Crusher Price . cement mill grinding media calculations – In the global have a. » More; calculation of grinding media in raw mill - . cement mill grinding media calculations – Crusher Price Our crusher have very leading status in mine industry ...

calculate the charging in cement mill pdf. how to calculate optimum grinding media and power for cement mill . in South Africa, the mill, the mill and used to calculate the rate . grinding volume calculation... or ball mill pdf, CGM Grinding Plant, cement ball mill grinding media calculation We ... cement plants ing up in india from november ...

how to calculate raw mill grinding media - . calculation of grinding media in raw mill -YouTube 21 Jan The Cement Grinding Office Modification of. Get Price. CEMENT FINISH GRINDING MILL BALL CHARGE CALCULATION. To get most out of the grinding media, Here is the method for correct calculation ofcement mill ball charge. Step 1 .

THE GRINDING CHARGE OF ROTARY MILLS Prof.Dr.Eng. Gh. Ene "Politehnica" University of Bucharest ABSTRACT This paper presents the achievemens of grinding charge for the tube mills with balls.The author shows charactheristic size of grinding media charge: bulk density, porosity, filling degree. Regarding this last size,the

Dec 08, 2009· Re: how to estimate the wear rate for Ball mill. Most practical way to by measuring empty height and calculating the % volumetric filling of grinding media.Alternative way to make track of mill main drive kW consumption reduction and add makeup .

important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media . Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills

Oct 19, 2017· It attached to the milling equipment (mill). Each mill manufacturer recommends certain grinding media type for mill operation under certain conditions: the crushed material parameters, the mill's performance, the raw materials particle size in the mill's "feed", and the required grinding fineness (finished class content).

It holds spherical, cylindrical or rod-like grinding media of size 15–100 mm that may be steel or a variety of ceramic materials, and occupy 20–30% of the mill volume. The shell of the mill is lined with steel or rubber plates. Grinding is effected by impact and attrition between the grinding media.

How To Calculate Grinding Media For Mill The FL ball mill is designed for grinding of clinker gypsum and dry or moist additives to any type of cement able for large grinding media and FL ball mill for cement grinding cement ball mill grinding media calculation Get Price calculation of ball mill media in ball mill.

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill's modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and application.

> Mining Equipment > how can i calculate optimum charge for cement mill; Print. how can i calculate optimum charge for cement mill. Posted at:January 8, 2013[ ... 3.2 Energy conservation technique in cement production process 3.2.1 Raw mill ... cement mill grinding media distribution.

calculate mill grinding media in cement - India . How about calculate mill grinding media in cement. magnetite calculate mill grinding media in cement is one of the most commonly used metallurgy,solid waste disposal ... cement mill grinding media calculations -Grinding mill

Table of ContentsData on Ball ChargesBall Mill Ball Wear ProjectionRecapitulation of Ball Wear FormulasPractical Application of Theoretical Conclusions In the previous discussion the fact was established that the work done by a ball when it strikes at the end of its parabolic path is proportional to its weight and velocity; then, since the velocity may be considered as constant for all the ...

how make cement mill grinding media calculation, Art calculation of grinding media in raw mill formula to calculate grinding media wear rate for cement . The cement mill. Bogue calculation; Cement, cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media .

degree of filling in raw mill calculation. Grinding Volume Calculation In A Ball Mill - Youtube. mill filling calculation sagmilling, ball mill volume. ... Grinding Mill Filling Calculations - Coal Crusher,coal . calculation of ball filling ratio in grinding mill. ... Tonnage of grinding media u can calculate on the basis of dia.length and the ...

How To Calculate Grinding Media Sizes For Ball Mill. How To Calculate Grinding Media Sizes For Ball Mill. Our company is one high-tech enterprise, which involves R&D, production, sales and service as .

Raw mill SEC (kWh/kg-mat'l) Oct.2 Oct.9 Oct.16 Oct.23 Oct.30 Nov.6 Addition of Grinding Balls Watch raw mill SEC daily and add grinding balls in right timing →10% energy saving expected Ball diameter shrinks as time passes due to erosive effect. This leads to gradual increase of raw mill SEC. Filling level of grinding balls is also important in

Sep 22, 2016· Discharging the Grinding Media of a BallMill. Discharging the Grinding Media of a BallMill. ... Small production ball mill for ore grinding - Duration: 2:42. mbmmllc 26,583 views.

how to calculate wet ball mill media weight · Choosing the Best Media Mill For Your Wet Grinding Application. Of course, every media mill manufacturer will give reasons why their equipment is . The quantity of product is normally expressed in a total slurry weight for coatings .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (e.g., via a hand crank), working animal (e.g., horse mill), wind or water ().