WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

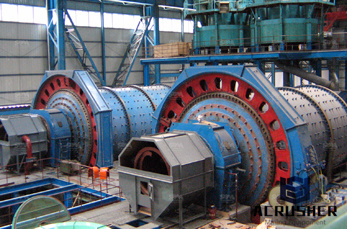

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Jan 07, 2015· Raw mills usually operate at 72-74% critical speed and cement mills at 74-76%. 3.2 Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg. w: Angular velocity of the mill tube in radial/second. w = 2*3.14*(n/60) Di: inside mill diameter in meter (effective mill diameter). n: Revolution per minute in rpm.

derivation of critical speed of ball mill. 20180807 · Mining Ball Mill For Hematite,Iron Ore,Copper Ore,Dolomite,Bentonite Place of Origin: Henan The point where the mill becomes a centrifuge is called the "Critical Speed" and ball mills usually operate at 65% to 75% of the critical speed.

Determining Energy Cost for Milling Solid Matter in a Ball Mill aidic. time spent on grinding by 28.9 % for cement clinker, 18.4 % for black coal, 28.9 where ωкр is calculated value of the critical velocity according to the formula, s-1; R is energy р and speed с of this process on the grinding mode coefficient ψ

Critical Speed Ball Mill For Glaze Grinding; High Performance Cement Ball Mill Critical Speed . High performance cement ball mill critical speed.Steel.Ball millement ball mill brief.Introduction cement ball mill grinds material by rotating a.Cylinder with steel grinding balls causing the balls to.Fallack into the cylinder and onto the material to be groundhe rotation.Is usually between 4 to 20.

The intermittent ball mill is a process in which the mass particle becomes fine powder by impact, extrusion, grinding and so on under the action of external force to overcome the stress when the object deforms and the cohesion of the particle.Because the intermittent ball mill structure is simple, the work is safe and reliable, the production adaptability is strong, can dry grinding or wet ...

Oct 19, 2006· What it is the optimun speed for a ball mill ? - posted in Pyrotechnics: I have done a ball mill, recenly finished, but the motor has too rpms, is too fast for use in a ball mill (the pvc cylinder that i use, left of the shafts). With the motor i will use a 40 mm pulley, because i have a 50 mm driven pulley, in one of my two shafts. In the other side of my shafts there are two 40 mm ...

20/06/2015 · The effect of Ball Mill RPM speed going from sub-critical to super-critical helps understand the Ball Mill Working Principles of ball-on-ball VS ball-on-shell grinding The Motion of the Ball Charge. Cement Ball Mill_Ball Mill,Ball Mill Supplier,Ball Mill .

All Ball mill or tube mill calculation, Critical speed, Ball Size calculations, Separator efficiency, Mill power cnsumption calculation, production at blain Home Cement Manufacturing

Aug 23, 2018· CRITICAL SPEED OF THE BALL MILL Let a grinding ball of mass m is in motion in a mill of diameter D meters It is at a position making an angle a at the center (called the angle of repose). The force acting on the ball are described in the figure The centripetal force acting [.]

Figures 8.5 for the popular mill types. 3 c is the mill speed measured as a fraction of the critical speed. More reliable models for the prediction of the power drawn by ball, semi-autogenous and fully autogenous mills have been developed by Morrell and by Austin. (Morrell, S. Power draw of wet tumbling mills .

What is the ball mill critical speed and how to improve ball mill efficiency ? . speed is hard to calculated, and . Cement Ball Mill grinder manufacturer,ball grinding machine . A ball mill is a horizontal cylinder partly filled up with steel balls (or occasionally other shapes) that rotates on its axis, .

Cement ball mill - CHAENG. CHAENG cement ball mill equipment can reduce energy consumption by 30% and increase the processing amount by 15-20% after transformation. the cement ball mill can perform dry process production and also wet process production, moreover it can do grinding and drying at the same time. >> Ver Precio; Ball Mill

Cement mill - WikipediaA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into

Mill Speed - Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

BALL Mill Critical Speed % Critical speed: Practically, mill speed between 68 and 82% of critical speed. % critical speed is the mill actual speed in RPM divided by nc. Example: 3.98 meter mill with rotational speed of 15.6 rpm then nc = 21.2, % critical speed = 73.6 %.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and non-ferrous metals. The ball mill can grind various ores and other materials either wet ...

formula for maximum ball size in cement mill, ball mill ... ball mill grinding media calculation, formula for maximum ball size in cement mill Chat Now; ball mill speed calculation formula for wet grinding - YouTube ball mill speed calculation formula for wet grinding, Links: ... ball mill speed calculation formula for wet grinding, Links ...

Quality cement grinding mill supplier on sales from cement grinding mill manufacturer – find China cement grinding mill factory, suppliers from Zhengzhou .

The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed. Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns.

Cement Ball Mill, You can Buy good quality Cement Ball Mill of page 4, we are Cement Ball Mill distributor & Cement Ball Mill manufacturer from China market. Home Products About Us Factory Tour Quality Control Contact Us. Request A Quote.

Energy-Efficient Technologies in Cement Grinding. ... Water demand and setting times are similar to that of a ball mill cement under comparable conditions . Figure 7. Loesche vertical roller mill [8]. ... The shell rotates faster than the critical speed which leads to centrifuging of the material. The main feature is the roller inside the shell ...

Determining Energy Cost for Milling Solid Matter in a Ball Mill - aidic. time spent on grinding by 28.9 % for cement clinker, 18.4 % for black coal, 28.9 There is a big amount of grinding machines, among which ball mills where ωкр is calculated value of the critical velocity according to the formula, s-1; R is .

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical ...