WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

This machine used for making ceramic bowl,plate,cup automatically. Nomal work together with Dryer /Drying line as a semi-auto production line. Hydraulic Vertical Auto Roller Head Forming machine. ... This is a fully automatic forming production line. Pug mill-clay cutting-foming-driying-demolding-edge trimming, all process finished ...

Great Wall Heavy Industry specializes in producing mining equipment,supply ball mill,raymond mill,vertical roller mill,High-Pressure suspension mill,Three-Ring micro powder mill,etc.

Vertical roller mill Introduction. The vertical roller mill which belongs to equipment for fine grinding, fine grinding of hard and medium hard or soft material in the building materials industry, especially used in the cement industry, ceramic industry, power sector, such as cement clinker, limestone, clay, China clay, feldspar, gypsum, barite and coal etc..

Feb 17, 2016· In this training module, we'll cover the operation of a vertical roller mill. This mill is commonly used in the cement industry in order to grind raw .

Alibaba offers 4,938 vertical roller mill products. About 56% of these are mine mill, 2% are cement making machinery, and 1% are cable manufacturing equipment. A wide variety of vertical roller mill options are available to you, such as raymond mill, ball mill.

Oct 10, 2019· where users share latest tips, hacks, Technology, cryptocurrency and world news across all topics

Steel Slag Vertical Mill; Clinker Grinding Unit; Coal vertical mill; Slag Vertical Roller Mill; Raw material vertical mill; Vertical cement mill

Outotec HIGmill High Intensity Grinding Mill. ... Because of the tall and narrow vertical mill body arrangement, grinding media is evenly distributed and mineral particles remain in constant contact, significantly increasing grinding efficiency. ... On-line particle size .

Expect the highest mill availability! Mostly supplied in segmented parts, occasionally as monobloc casting, the grinding table receives the material grinding bed submitted to the tires pressure as per the vertical mill working principle. Hence those parts need outstanding wear resistance. Magotteaux offers a vast choice of alloys with or without ceramic grains (MMC – Metal Matrix Composite ...

Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries. Plant engineering solutions for any mission | Loesche

LM Vertical Grinding Mills. According to customers' requirements, HSK success in absorbing foreign experience and world-advanced technology,. Read More

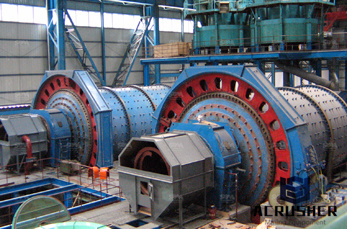

Ball Mills The TAURUS line of ball mills from ECUTEC are commonly used to mill granular materials into fine powders at very high throughputs. KGM mills are available in sizes ranging from pilot scale lab units to mills exceeding 1000kW. Each mill is custom designed for the application and can be configured for use with steel or ceramic grinding media.

LM Vertical Roller Mill. LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying. It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protection.

Longyan Yifeng Grinding Mill Co., Ltd was established in 2002, it has been cooperating closely with many Scientific Research Institutions and Universities across the country since the beginning of foundation, it has also been one of the executive members of...

Jan 13, 2015· Introduction of Raymond mill: YGM series Raymond Mill is the new type Raymond mill of our company, which is suitable for processing various .

The vertical ultra fine grinding mill is an important equipment in modern mine milling equipment. It is also a new vertical ultra fine grinding mill that Shanghai Clirik has improved on the basis of the original mill. After the new generation, the new vertical ultra fine grinding mill has a large production capacity and low power consumption, making it an ideal choice for processing limestone.

Largest vertical roller cement mill Guinness World. The largest vertical roller cement mill is the FL OK816 vertical mill with a grinding table diameter of 808 m 26 ft 6 in and roller diameter of 264 m 8 ft 7 in achieved by Shah Cement Industries Ltd Bangladesh located in Dhaka Bangladesh on 6 September 2018.

If you're looking for high quality used ball mills to use in your manufacturing processes, you're in the right place. We provide used ball mills at a reasonable price. Both ball and pebble mills work by impact and attrition – a cylinder rotates and moves either balls or pebbles around to grind materials into fine powder.

CERAMIC TECHNOLOGY OFFERED IN TWO GRADES ... For more information on Magotteaux's complete line of Vertical Roller Mill Castings and on our overall product lineup and other innovative solutions, contact your regional Magotteaux sales office, or mail us at: cement&utilities@magotteaux

Stirred Mills have been proven to provide energy savings compared with traditional ball mills. The finer the product required, the more efficient stirred mills will be than a ball mill. The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills more energy efficient grinding machines.

Vertical Impact Mill Powder Grinding Mill Manufacturer Founded in 2000, Weifang Zhengyuan Powder Engineering Equipment Co., Ltd. is a worldwide famous superfine new material equipment manufacturer, whose production scale and sales performance are in the leading position in this industry.

Ball mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc. According to the need of customers, ball mills can realize both wet and dry production. Ball mills have been designed in standard sizes of the final products between 0.074 mm and 0.4 mm in diameter.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Lvssn provides various grinding equipment for cement production line, including: Grinding mill,Ball mill,Rod mill,Roller press,Veritcal mill,Pipe mill